Data Center Design

Engineering Services

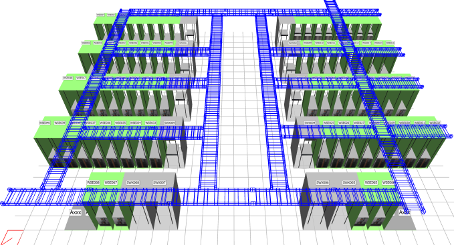

We build your cabling system in digital twin models before building it in real life

Data Center Cabling Projects Are

Complex, Error-Prone, And Time-Consuming

MANUAL METHODS DON'T SCALE

Field Measurements

Manual tape-and-estimate across complex pathways

Spreadsheet BOMs

Copy-paste errors in thousand-line cable lists

Generic Labels

Bulk shipments with no install context

The result: rework, delays, and blown install budgets. These aren't edge cases — they're the norm on complex deployments. And they're entirely avoidable.

What if you could validate every cable run before manufacturing begins?

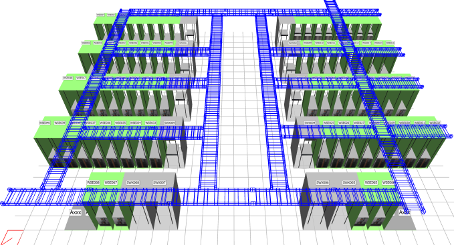

Interactive 3D Data Center Model

Validate every cable route before manufacturing begins

We Engineer Your Complete Cabling System

Before You Build It

You Provide

inputs you already have

- Rack layouts (CAD, Visio, or PDF)

- Port assignment spreadsheet

- Floor plan with tray/conduit paths

We Engineer

errors caught early, not on-site

- Build 3D digital twin of your environment

- Route cables through actual pathways

- Calculate precise lengths with service loops

- Validate for conflicts before production

You Receive

One PO. Less field trauma

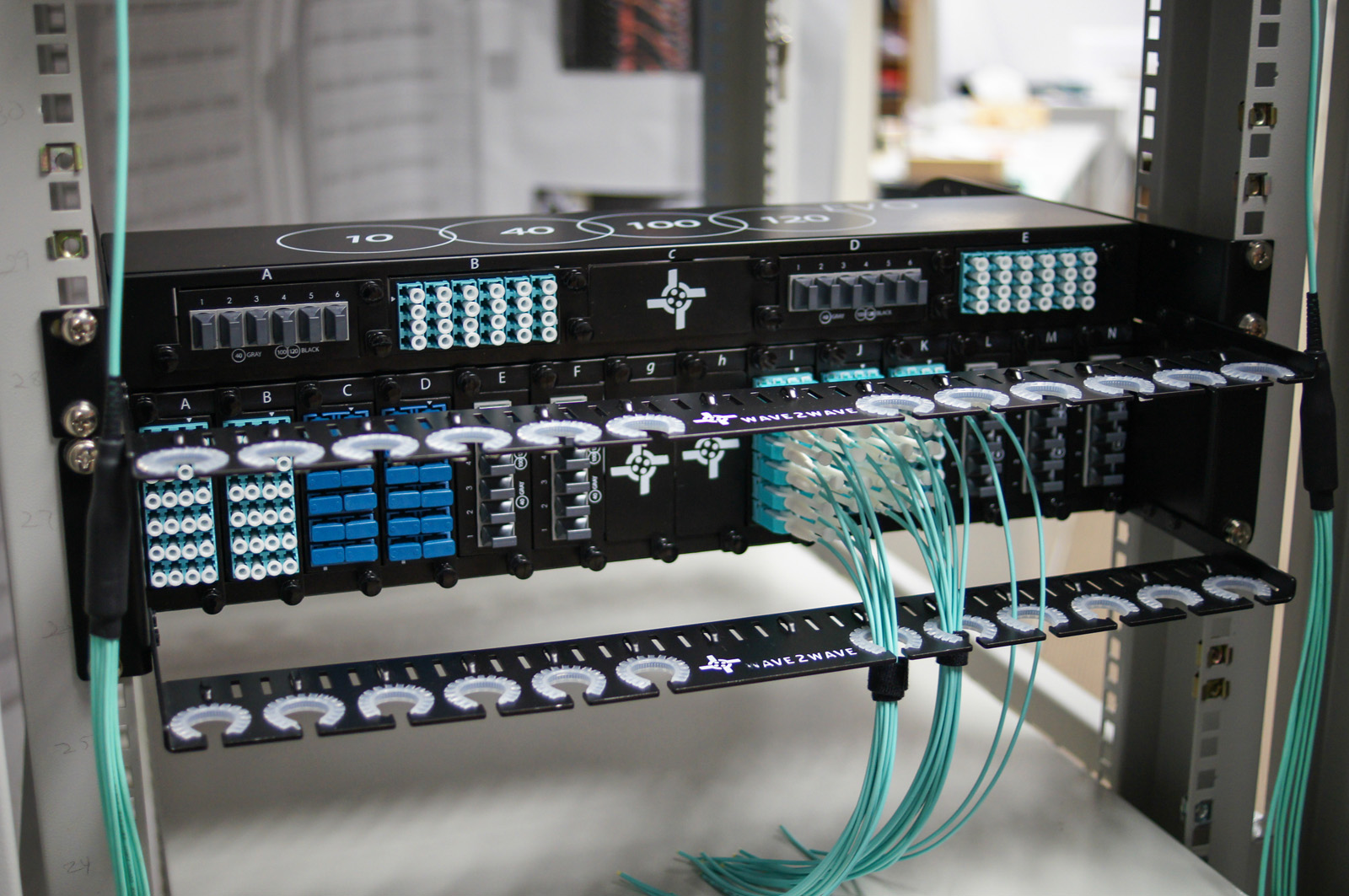

- Factory-terminated cables, exact lengths

- Pre-labeled by rack, port, and circuit

- Installation-ready kits, sorted by sequence

- Complete documentation package

Traditional Method

Manual planning, prone to errors

DC Twin Engineering

Automated, validated, error-free

These Are Your Inputs

Give us your spreadsheets, port maps, and floor plans — we handle the rest

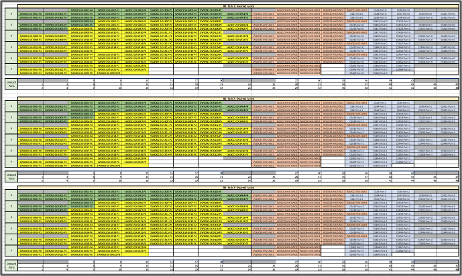

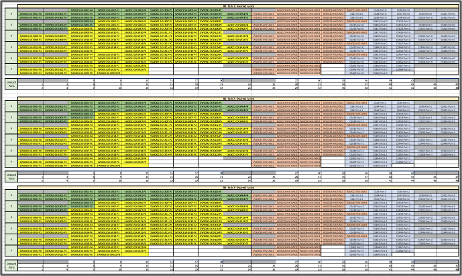

Complex Spreadsheets

Rack layouts, equipment specs, power requirements — we parse thousands of rows to build your digital twin

Port Mappings

Color-coded connection tables showing source and destination for every cable run

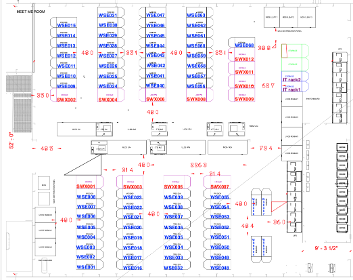

2D Floor Plans

Rack positions and cable paths in CAD, Visio, or PDF format — we convert to 3D models

The Transformation

See every cable path before a single connector is terminated

Before: Manual Methods

Field Measurements

Tape measure guesswork, wrong cable lengths

Spreadsheet BOMs

Error-prone manual tracking, version chaos

Generic Labels

Impossible troubleshooting in production

After: Digital Twin

Exact Cable Lengths

3D path calculations to the centimeter

Automated BOMs

Zero errors, single source of truth

Custom Labels

Source-to-destination printed on every cable

100%

Path Validation

0

Field Errors

Exact

Cable Lengths

What You Receive

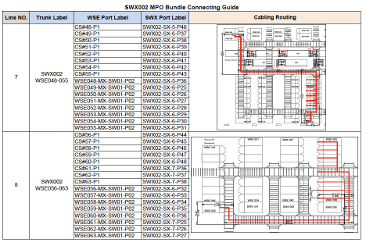

Complete documentation and installation-ready kits

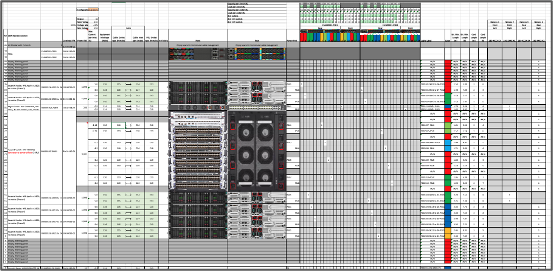

Rack Elevations

Visual rack layouts with cable schedules — your single source of truth

- Detailed rack front/back views

- Port-level connection diagrams

- Cable routing visualization

Installation Guides

Guides ship with your kits — installers know exactly what goes where

- Bundle-by-bundle instructions

- Visual routing diagrams

- Floor plan overlays with cable paths

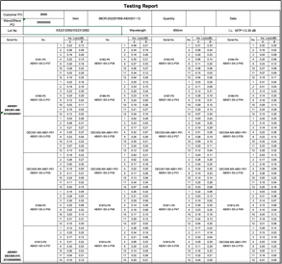

Test Reports

Complete test data for audit trails and quality assurance — no field testing surprises

- Insertion loss verification

- By server, rack, individual cable

- Compliance documentation included

Why Digital Engineering Matters

Traditional methods lead to errors, delays, and costly rework. Digital engineering eliminates these problems at the source.

Manual Measurements

Tape-and-estimate guesswork leads to wrong cable lengths

Spreadsheet Errors

Copy-paste mistakes and version control chaos

On-Site Conflicts

Discover routing problems during installation

Generic Shipments

Hours wasted sorting bulk cables on-site

Emergency Rework

Costly reorders and on-site troubleshooting

Exact 3D Calculations

Precise cable lengths calculated in digital twin model

Automated Validation

Zero errors—validated before production begins

Pre-Resolved Conflicts

Fix routing issues in software, not on-site

Pre-Labeled Kits

Sequenced bundles ready for immediate installation

Zero Rework

Perfect accuracy eliminates reorders and delays

The Result

95%

Fewer Errors

60%

Faster Deploy

0

Field Surprises

Ready to Engineer Your Data Center in Digital Twin?

Contact us to discuss your project and receive a consultation on how digital engineering can eliminate errors and accelerate your deployment.