Custom Engineering – Cables & Systems Built to Your Spec

No guesswork, no off-the-shelf compromises. We work from your design (DCIM models, CAD drawings) to create bespoke cabling systems built exactly to fit your project.

Request a QuoteEnd-to-End Custom Engineering Services

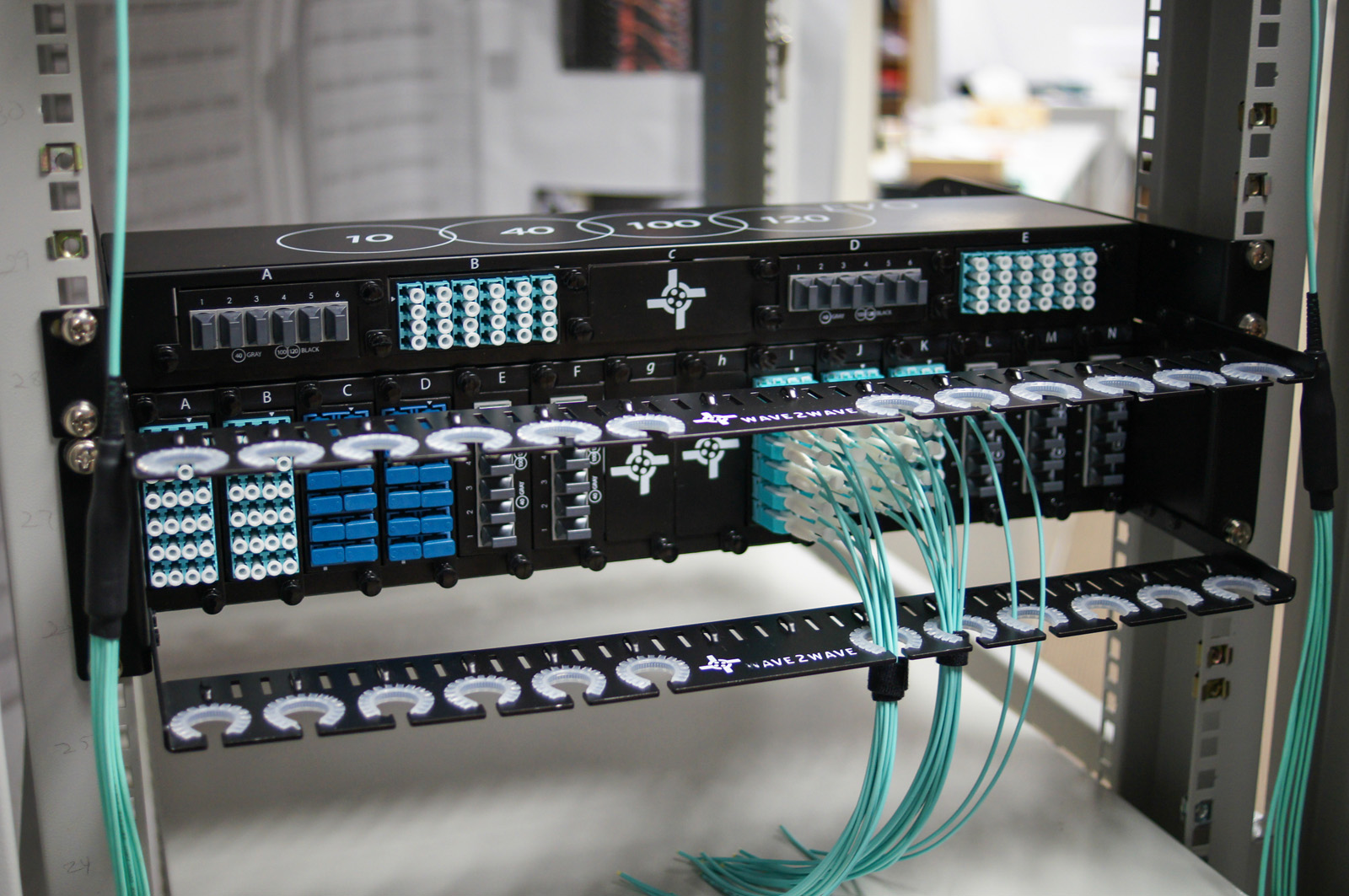

Unlike catalog vendors with fixed lengths, Wave2Wave cables are engineered to your exact rack geometry, manufactured in 3-inch increments for an exact fit. From pre-engineered bundles to factory labeling and deployment kitting, we transform complex cabling requirements into factory-validated, ready-to-install solutions.

Cable Bundles

Pre-engineered cable bundles under one SKU. Simplify procurement, reduce logistics complexity, and eliminate ordering errors for complex deployments.

Factory Labeling

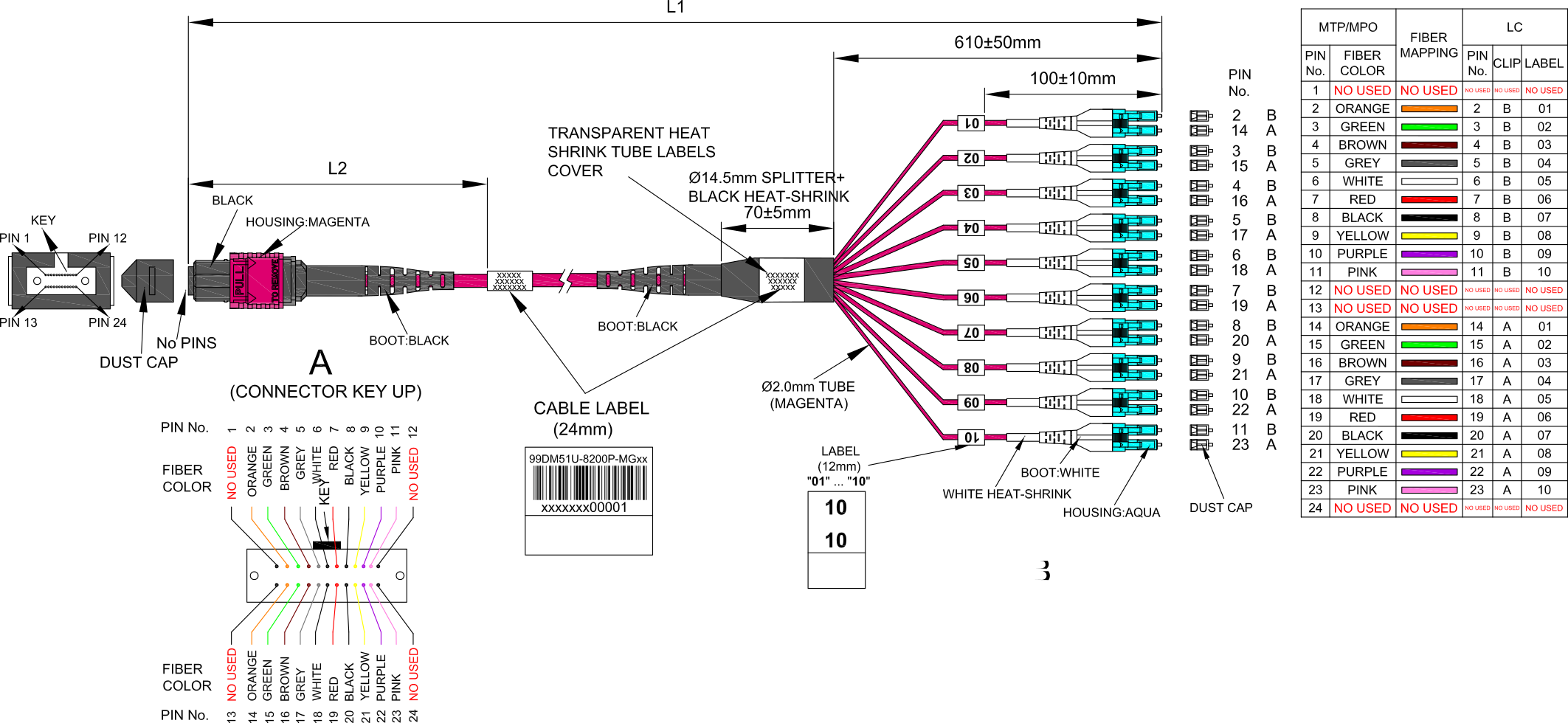

Pre-labeled cables eliminate field errors and reduce installation time by 75%. Every cable arrives with permanent identifiers tied to your rack and port mapping.

Factory Kitting

Rack-specific cable kits organized by installation phase. Reduce deployment time 50-75% with cables organized exactly as needed for installation.

DC Twin™ Digital Modeling

Create a virtual replica of your data hall, validate every cable route, and eliminate surprises before production. 95% fewer errors, 60% faster deployment.

Why Custom Engineering?

Move complexity from the chaotic field environment into our controlled factory setting

Faster Deployment

Factory pre-termination, labeling, and kitting eliminate on-site work, reducing installation time by over half.

Error Reduction

Factory quality control and DC Twin™ validation eliminate field termination errors and port mapping mistakes.

Factory Tested

Every cable is tested in our ISO-certified facility before shipment. No field failures, no rework truck rolls.

Custom Engineering Process

Receive Your Design

DCIM export, CAD drawings, or spreadsheets – we work with whatever format you have.

Engineering Review & Optimization

Our engineers review your design, recommend optimizations, and create production specifications.

Factory Manufacturing

Custom lengths (3-inch increments), factory termination, labeling, and kitting – all under one roof.

100% Quality Testing

Every cable tested for continuity, insertion loss, return loss, and polarity verification before shipment.

Delivery with Documentation

Complete test reports, installation guides, and visual diagrams included with every shipment.

Ready to Discuss Your Custom Cabling Needs?

Contact our engineering team today to discuss how we can design and build the perfect cabling solution for your data center.