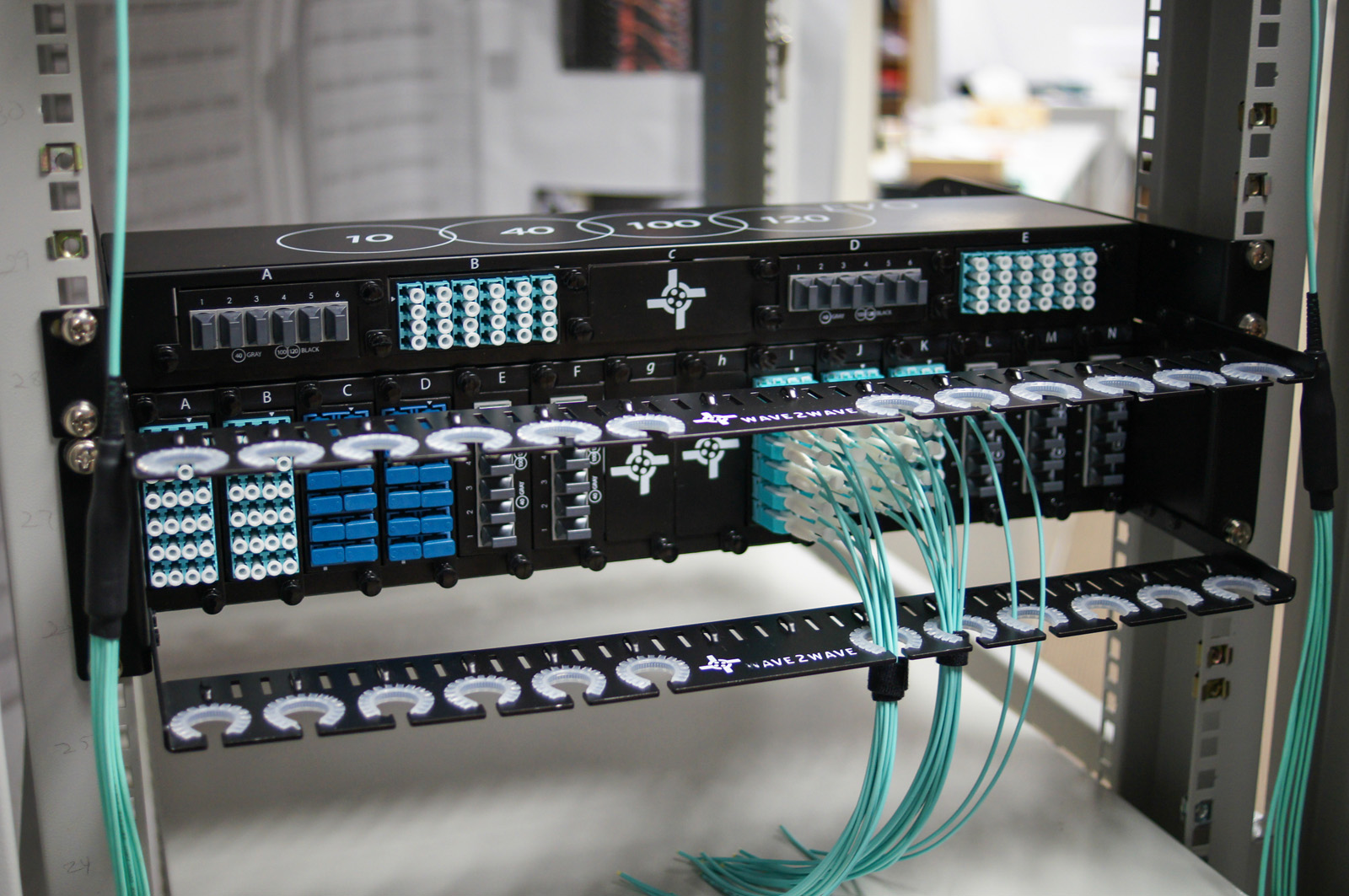

Factory Kitting – Organized for Speed

Rack-specific cable kits organized by installation phase. Your installers receive exactly what they need, when they need it – no sorting through hundreds of cables.

Request a QuoteCustom Kitting Solutions

Pre-organized cable kits eliminate sorting, reduce errors, and accelerate deployments. Each box contains exactly what installers need—nothing more, nothing less.

Rack-Specific Kits

Each box contains every cable, cord, and accessory needed for one rack. Open the kit, build the rack—no sorting required.

Row/Zone Kits

Materials packaged by row or cage to match site deployment order. Large-scale installations stay coordinated and efficient.

Phase-of-Work Packaging

Kits aligned with project stages—core infrastructure, distribution layer, server cabinets. Install in the right sequence, every time.

Complete Kitting Solutions

From pallet to port—every stage of your deployment organized for speed

Pallet

Bulk shipment organization—entire rows or zones palletized together for efficient logistics

Box

Rack-specific cartons—one box per rack with everything needed for complete installation

Packaging

Professional labeling and organization—cables sorted and marked for instant identification

Cabling

Pre-sorted cable bundles—grouped by type, length, and destination for seamless installation

Factory-organized cable kits eliminate field sorting and reduce installation time by 50-75%

Measurable Impact on Every Project

Factory kitting eliminates the chaos of bulk shipments and transforms installation logistics

Error Reduction

Prevents mix-ups from bulk shipments. Every cable arrives in the correct kit, labeled and ready to install.

95%

Fewer installation errors vs. bulk shipping

Faster Installs

Techs open one kit and immediately build the rack. No sorting, no searching, no delays.

50-75%

Reduction in installation time

Clean Logistics

Labeled boxes streamline site delivery and inventory. One box per rack eliminates receiving chaos.

60%

Labor cost reduction from simplified logistics

Deployment Timeline Comparison

See how factory kitting transforms data center deployment timelines

Bulk Shipment Approach

8-12 weeks

1000-rack data center deployment

On-site cable sorting

Installers waste time organizing materials

Manual field labeling

Labels created during installation

5-10% error rate

Costly rework and delays

Factory-Organized Kits

3-4 weeks

Same 1000-rack deployment

Pre-sorted by rack

Zero field sorting required

Factory pre-labeled

Professional labels before shipment

<0.5% error rate

Factory QA ensures accuracy

50-75% Reduction in Installation Time

GPU clusters online weeks earlier, revenue generation accelerated

95%

Error reduction

60%

Labor cost savings

1 Box

Per rack = simplified logistics

Factory Kitting Process

From bulk materials to install-ready kits

Cable Selection

Match to DCIM data

Labeling & Organization

Rack-specific sorting

Quality Verification

100% kit validation

How Kitting Works

Four simple steps from deployment plan to completed installation

We receive your deployment plan

DCIM export, rack elevation, or spreadsheet—any format works

We organize cables by rack and phase

Power → Network → Storage → Management—in the sequence you'll install them

Each kit ships with installation guide

Visual diagrams showing exactly where each cable goes—no guesswork

Installers complete racks in record time

50-75% faster than traditional methods—deployment timelines collapse

Ready to Accelerate Your Deployment?

Learn how rack-specific kitting can transform your next data center build.