Quality Assurance in Custom Cable Manufacturing

Quality assurance in custom cable manufacturing is the foundation of reliable network performance and the key to preventing costly deployment failures. This behind-the-scenes look explores the rigorous processes and methodologies that ensure every cable assembly meets exacting standards and performs flawlessly in demanding environments.

Our Quality Philosophy

Quality isn't just a checkpoint—it's embedded in every stage of our manufacturing process. From incoming material inspection to final packaging, we maintain rigorous standards that exceed industry requirements and customer expectations.

The Quality Assurance Framework

Our comprehensive quality assurance framework encompasses every aspect of the manufacturing process, from supplier qualification to final product delivery. This systematic approach ensures consistent quality and reliability across all product lines and custom configurations.

1. Incoming Material Inspection

Raw Material Verification

Every batch of raw materials undergoes comprehensive inspection before entering our production environment:

- Cable specifications: Jacket material, conductor gauge, and impedance verification

- Connector quality: Dimensional checks, plating thickness, and contact resistance

- Fiber optic testing: Attenuation, bandwidth, and numerical aperture measurements

- Documentation review: Certificates of compliance and material traceability

- Environmental testing: Temperature cycling and humidity resistance validation

Supplier Qualification Program

Our supplier network undergoes rigorous qualification and ongoing monitoring:

- Facility audits: On-site inspections of manufacturing processes and quality systems

- Performance monitoring: Statistical tracking of defect rates and delivery performance

- Quality agreements: Detailed specifications and compliance requirements

- Continuous improvement: Regular supplier reviews and capability assessments

2. Manufacturing Process Controls

In-Process Monitoring

Quality checkpoints throughout the manufacturing process ensure consistent results and early detection of potential issues:

Real-Time Monitoring

- Termination process parameters

- Dimensional verification systems

- Visual inspection protocols

- Environmental condition tracking

Process Documentation

- Detailed work instructions

- Operator certification records

- Parameter logging and analysis

- Non-conformance tracking

Statistical Process Control

We employ advanced statistical methods to monitor and control manufacturing processes:

- Control charts: Real-time monitoring of critical process parameters

- Capability studies: Regular assessment of process performance and stability

- Trend analysis: Predictive monitoring to prevent quality issues

- Root cause analysis: Systematic investigation of any quality deviations

3. Comprehensive Testing and Validation

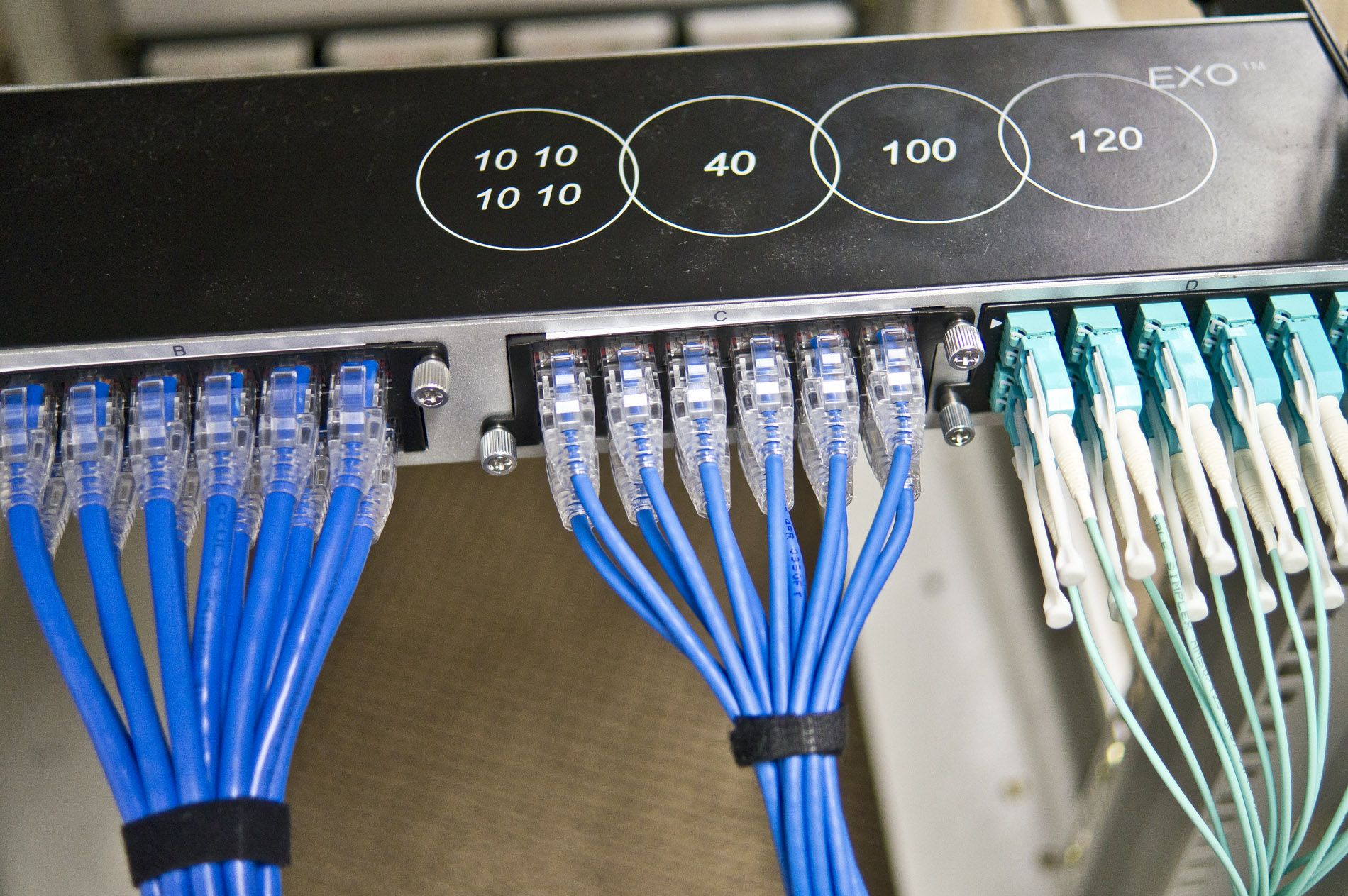

Electrical Testing (Copper Cables)

Every copper cable assembly undergoes comprehensive electrical testing to ensure performance specifications are met:

- Continuity testing: Verification of all conductor paths and pin assignments

- Resistance measurements: DC resistance and impedance characterization

- Insertion loss: Signal attenuation across the frequency spectrum

- Return loss: Reflection characteristics and impedance matching

- Crosstalk testing: NEXT, FEXT, and alien crosstalk measurements

- High-voltage testing: Insulation integrity and safety verification

Optical Testing (Fiber Cables)

Fiber optic assemblies undergo specialized testing to ensure optimal light transmission:

- Optical loss measurement: Insertion loss across all operating wavelengths

- Return loss testing: Reflection characteristics at connector interfaces

- Polarity verification: Fiber mapping and continuity confirmation

- End-face inspection: Microscopic analysis of connector geometry and cleanliness

- Bandwidth testing: Modal bandwidth and dispersion characteristics

- OTDR analysis: Length verification and fault detection

Environmental and Reliability Testing

Products undergo rigorous environmental testing to ensure long-term reliability:

- Temperature cycling: Performance verification across operating temperature ranges

- Humidity testing: Moisture resistance and condensation effects

- Vibration testing: Mechanical stress and connection integrity

- UV exposure: Aging tests for outdoor and plenum applications

- Salt spray testing: Corrosion resistance for harsh environments

4. Final Inspection and Documentation

Final Quality Verification

Before packaging, every cable assembly undergoes a comprehensive final inspection:

- Visual inspection: Complete examination of all components and connections

- Label verification: Accuracy and placement of all identification labels

- Length measurement: Precise verification against customer specifications

- Packaging assessment: Protection adequacy and handling instructions

- Documentation review: Completeness of test reports and certificates

Traceability and Documentation

Complete documentation ensures full traceability and compliance:

- Comprehensive test reports with all measurement data

- Certificates of compliance for industry standards

- Material traceability records linking to source batches

- Quality control sign-offs and approval documentation

- Customer-specific documentation and labeling requirements

- Calibration certificates for all test equipment used

5. Continuous Improvement Program

Our quality assurance program includes ongoing analysis and improvement initiatives:

- Quality metrics analysis: Regular review of defect rates and performance trends

- Customer feedback integration: Systematic incorporation of field performance data

- Process optimization: Continuous refinement of manufacturing procedures

- Technology updates: Investment in advanced testing and manufacturing equipment

- Training programs: Ongoing education for quality and manufacturing personnel

Quality Results

Our comprehensive quality program delivers measurable results:

- 99.8% first-pass yield rate on all products

- Less than 0.1% field failure rate

- 100% on-time delivery of quality products

- Zero customer complaints related to quality issues

Our Quality Guarantee

Every Wave2Wave.io cable assembly comes with our comprehensive quality guarantee, backed by detailed testing documentation and full material traceability. This commitment to quality ensures that our customers receive products that not only meet their specifications but exceed their expectations for performance and reliability.

Our quality assurance program represents more than just compliance—it's our commitment to your success. When you choose Wave2Wave.io, you're partnering with a team that understands that quality isn't negotiable, and that every cable we manufacture carries our reputation and your trust.

Experience Our Quality Difference

Learn more about our quality assurance processes and how they ensure reliable performance for your critical infrastructure projects.

Discuss Quality Requirements